The raw material of the formboard top pine facade system is a wooden board with polyurethane bonding. These highly compressed wood-based boards are cut using laser technology and coated with diffusible wood-stain finishes in an industrial application process before they are delivered, including perforations, morticing required for installation and the support system with fixings. Designs using these boards are subject to timber construction regulations and also local building byelaws.

The design of the wood protection details has a significant effect on the durability of the boards and the required maintenance intervals. It is therefore important to take account of local weather conditions such as exposure to hail and snow. The carrier board can be delivered in any RAL and NCS color or one of the 11 Bruag ALU metallic colors.

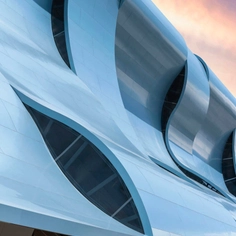

The individual facade system allows complete customization including perforations. Thanks to the laser technology used to create the perforated panel facade, almost anything is easily realizable. Each element is precisely designed, keeping in mind specifications, cut to the nearest millimeter in accordance with blueprints, and coated in one of over 3000 available UV-resistant color tones. The edges of the perforated panels are coated in a color of choice (RAL, NCS S, Bruag Alu or Les Couleurs® Le Corbusier). Large format panels can be produced. Bruag will calculate the net amount used so wastage and pre-drilled holes are not factored into the final price.

In addition to freedom in terms of planning, laser-cutting allows you to give the panels a completely individual design. You can design your very own perforations in DXF or DWG formats, or select a pattern from those already available.

Features and Benefits

- Individual shapes (incl. perforations and ornamentations) made possible by use of laser-cutting technology

- Eco-friendly

- An attractive price-performance ratio (based on purchase price, incl. wastage)

- Moisture-resistant

- No particle loss as a result of moisture that originates from the bonding process

- Frost-proof

- High fracture strength

- Large formats (up to 6.20m) with no price premium

- Extensive choice of colors (over 3000)

- Straight-forward installation

Comparison Facade Material CELLON and Formboard top pine Bruag

| | Formboard top pine | CELLON® |

| Carrier Plate | Highly-compressed bonded wood-based panels | Compact high-pressure layered panel from pressed material (HPL): 70% cellulose layers and 30% phenolic resin |

| Thickness | 10 or 18mm | 6, 8 or 10 mm (other thicknesses available on consultation) |

| Raw material maximum format | 18x6200x2100mm; 10x6100x2100mm* | 6/8/10x3630x1860mm or 6/8/10x3050x1300mm* |

| Charging | Net calculation | Net calculation |

| Colour Choice | NCS S edition 2, RAL, Bruag ALU, Les Couleurs® Le Corbusier | NCS S edition 2, RAL, Bruag ALU, Les Couleurs® Le Corbusier |

| Building material class | B2 = B1 standard with special coating available (additional charge) | Bs1d0 = standard |

| Mounting method | HolzFix stainless steel screws + sealing ring (holes lasered in keeping with your specifications, at no additional cost) | HolzFix stainless steel screws + sealing ring (holes lasered in keeping with your specifications, at no additional cost) |

| Substructure | Back-ventilated, vertical composite min. 27*80mm;

metal substructure also available | Back-ventilated, vertical composite min. 27*80mm;

metal substructure also available |

* The maximum width for Bruag's industrial coating machine is 1.33m. Panels that are over this size can be hand-coated (for an additional charge).