Terrazzo has long stood at the intersection of durability, artistry, and timeless appeal. Originating in Italy as a pragmatic way to reuse marble fragments in flooring, terrazzo has since become synonymous with elegance and strength in architecture. Traditionally crafted by hand using stone chips and lime and later, cement, it created continuous, seamless surfaces that celebrated both craftsmanship and endurance. Over time, as construction methods evolved and projects began to demand greater efficiency, adaptability, and modularity, terrazzo expanded beyond its traditional limits. From poured-in-place systems to modern epoxy-based formulations, it has evolved into a versatile material that enables thinner sections, faster installation, and a wider range of colors and aggregates. Today, precast terrazzo complements the traditional method, unlocking new applications without compromising performance or beauty, from stairs and wall cladding to furniture and custom design elements.

The distinction between poured-in-place and precast terrazzo lies primarily in their fabrication and installation methods. In the poured-in-place option, aggregates and epoxy binders are poured, cured, leveled, and polished directly on site. The result is a continuous surface with virtually unlimited design possibilities, ideal for large horizontal applications as floors. This method, however, relies heavily on specialized labor, time, and site conditions.

By contrast, precast terrazzo is fabricated off-site in controlled factory settings, where elements such as panels, stair treads, risers, or wall cladding are cast, cured, and finished before being delivered to the project location. The industrialized process ensures consistency, reduces installation time, and allows architects to think of terrazzo as a modular building component rather than merely a flooring finish, transforming terrazzo from a continuous, essentially horizontal finish into a flexible system of parts that can be scaled, repeated, and customized throughout the building.

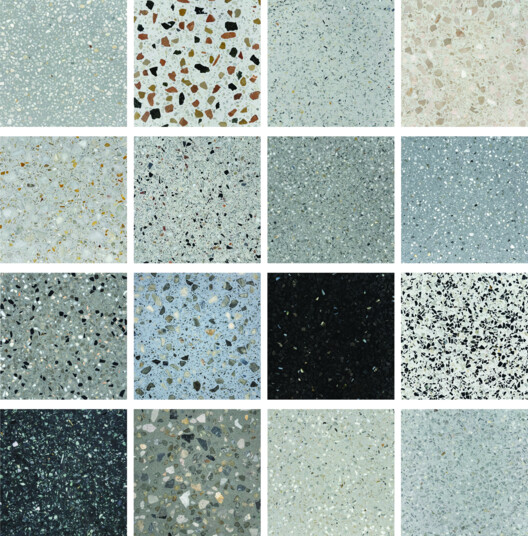

Precast pieces achieve high compressive strength using epoxy resin (above 10,000 psi / ≈ 70 MPa), withstanding heavy traffic and prolonged use. The factory curing process also eliminates environmental variables and ensures consistent finishing, while water absorption is virtually zero (< 0.01%), reinforcing dimensional stability. In terms of safety, the material meets slip-resistance standards with a coefficient of friction ≥ 0.6. Among the most significant contributions of precast terrazzo is the way it expands the architectural palette:

-

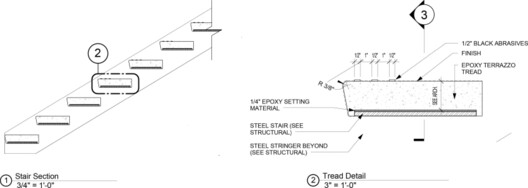

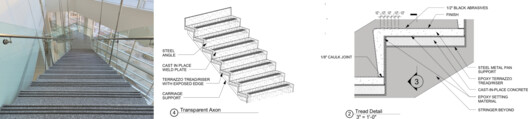

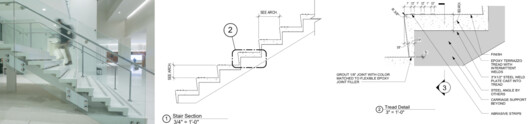

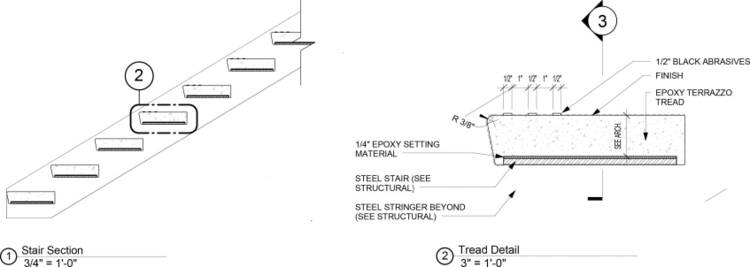

Stairs: Perhaps the most emblematic application of precast terrazzo is in stair construction. Instead of cladding concrete steps with separate finishes, precast terrazzo risers and treads arrive ready-made, designed to fit precisely into metal pans or be fixed to steel structures. The result is a durable, elegant, and modular system that balances performance with aesthetic continuity. Modularity ensures precise repetition, while customization allows for variations in dimensions, edge profiles, and embedded details.

-

Wall Cladding: Precast panels can also serve as vertical cladding. Lighter than stone but with similar durability, they give architects the ability to create continuous surfaces, rhythmic patterns, or bold graphic compositions.

-

Furniture and Special Elements: From benches and counters to custom furniture, precast terrazzo extends its versatility beyond the building envelope. Designers can explore its tactile richness and strength to create elements that connect architecture and interior design.

Going into Detail

The performance of precast terrazzo stairs and elements relies as much on precision manufacturing as on their integration with structural supports. For stairs, treads are factory-molded with a polished finish and abrasive inserts (½" anti-slip strips) embedded at the top to ensure safety in use. Pieces are typically installed over a metal support structure, such as a steel stringer or tray, using a ¼" epoxy setting bed that ensures leveling and adhesion. This arrangement eliminates the need for additional site-applied finishes, simplifying assembly and reducing execution variables.

Other details include rounded edges (R ⅜"), which prevent chipping and improve ergonomics. Each tread is an independent terrazzo piece supported on the steel structure. This solution favors serial repetition in large stair runs, maintaining visual consistency while also allowing for variation depending on the project (riser height, tread width, edge detailing).

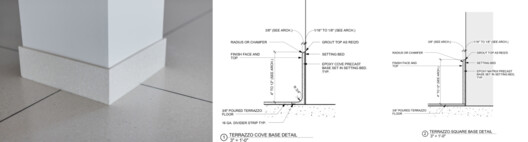

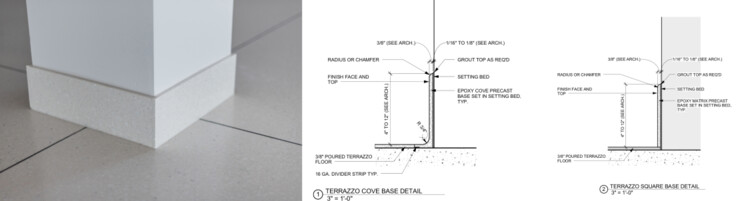

Precast terrazzo also stands out in baseboard details, ensuring precise transitions between floor and wall while protecting the lower portion of the wall. There are two main solutions: the square base and the cove base. The square base is made of simple vertical pieces, 4 to 12 inches high, installed over an epoxy setting bed with a thin grout line (1/16" to 1/8") at the top. This discreet solution provides a clean junction and is common in corporate or institutional spaces. The cove base, on the other hand, features a rounded lower corner (¾" radius), eliminating sharp angles and facilitating cleaning by preventing dust and moisture accumulation. This configuration is especially valued in hospitals, schools, kitchens, and laboratories, where hygiene and easy maintenance are priorities. Both base options can be finished with chamfers or bullnose edges, enhancing aesthetic continuity with the flooring and reinforcing the modular logic of the terrazzo system.

In summary, what makes precast terrazzo particularly compelling is the way it connects two seemingly opposite architectural values: craftsmanship and industrialization. On one hand, terrazzo remains tied to its artisanal origins, with aggregates, colors, and polished surfaces offering infinite variation and a handcrafted character. On the other, the precast process introduces efficiency, modularity, and precision associated with contemporary construction methods, allowing projects to balance strength and longevity with aesthetic versatility while meeting the modular logic of current building practices.