Kuraray facade systems were installed in the Montparnasse Tower in Paris, reducing the overall carbon footprint of the building. Originally built between 1969 and 1973, the tower is undergoing a major refurbishment, which has included replacing the existing facade with the intention of improving the building's environmental performance. The 40,000 m2 facade surface was replaced with laminated glass with a structural interlay from Kuraray.

Facade Design

The refurbishment project was designed by the architecture firm, Nouvelle AOM. The facade was divided into six principal typologies. Moving from the top to the bottom of the building, these included:

- The serre (2,450 m2)

- The checkerboard facade (27,000 m2)

- The suspended garden facade (1,050 m2)

- The loggia facade (10,050 m2)

- The lobby facade (2,600 m2)

- The patio facade (1,500 m2)

With the facade adding up to 30% of the carbon footprint, it was important to consider every detail within the facade design.

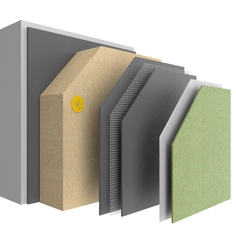

Structural Design of the Glass

The new facade was faced with a design challenge, as its added components meant there would be an additional weight on the existing building. Reducing the weight was important both to ensure the building's structural integrity was kept intact and to limit the carbon footprint.

Kuraray was asked to consult with this, needing to minimize the thickness of the laminated glass. As the main force acting on the facade elements is the wind load, wind tunnel tests were carried out to determine the exact wind load acting on the facade. Using these results, paired with the use of a structural interlay SG-5000, Kuraray's team was able to minimize the thickness of the laminated glass.

Benefits of Structural Interlayer

When compared to a standard PCB interlayer the overall glass composition (Kg/CO2eq/mm/m2) of the panels is significantly lower while maintaining the same structural integrity. Kuraray performed an analysis and calculations to determine the total reduction in carbon footprint when using their structural interlay. Focusing on the glass specified for the checkerboard facade, it was calculated that the carbon footprint was reduced by 15% when compared to the standard PCB interlayer.