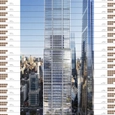

50 Hudson Yards will be New York City’s fourth-largest commercial office tower when it is completed in 2022. As part of the wider Hudson Yards development on the western edge of Manhattan, the tower will be 985 feet tall and span 3 million square feet.

PARKLEX PRODEMA interior wood cladding NATURHARDPANEL-W is being used to cover the interior walls of every bathroom on each floor of the tower, coming to a total of 58 bathrooms. The panels are water-resistant, allowing for a combination of the elegance of natural wood with the high performance required for bathroom materiality. The panels had to be adapted to meet the needs of the architect from the architecture studio, Foster+Partners.

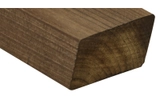

Choosing the Walnut Veneers

The walnut veneer panels were chosen for their intense dark brown color, which is unique to other known veneers, as well as having a grain mainly consisting of different figures and shapes called cathedrals, rather than a rift-cut straight grain.

Treatment

The interior wood cladding panels had a special treatment applied to the wood to make it moisture-resistant. A transparent film - made from a 0,6 mm thick paper, that was soaked in melamine resin, and rolled for handling - was placed on the top part of the veneer. The film has several duties. One of them is to protect in the event of contact with any substance. It also protects against moisture. On the bottom part of the veneer is another resin-soaked paper, creating a protective sandwich on both sides.

Selecting and grouping the Veneers for Each Room

The wooden veneers for each bathroom had to undergo a thorough selection process. The wood veneers were purchased with a special measurement, as well as having a custom quality and color parameters for the natural wood finish. The client requested that there be uniform colour, but no repeated grain. This was accomplished by purchasing a total of 900 veneers, which were then classified by tone and grain type. This made a total of 177 sequential groups, which were then distributed throughout the building's bathrooms.

Benefits of using Parklex Prodema's Moisture-Resistant Wood Panels

- Visual

Being made from real wood, PARKLEX PRODEMAPanels offer a natural variation in color and tone. The individuality of each panel lends to the creation of a unique visual aesthetic to any project. In the case of Hudson Yards, a unique finish was achieved after months of thorough research and development by the PARKLEX PRODEMA technical team. - Fire protection

PARKLEX PRODEMA panels have Class A protection against surface burning (according to the ASTM E84 standard test method). This is accomplished due to flame retardants embedded within the panels. - Suitable for humidity

The moisture-resistant property of the interior wood cladding panels makes them perfectly suitable for humid conditions and areas that come into frequent contact with water. - No maintenance

The surface composition of PARKLEX PRODEMA panels means they require no maintenance, giving them lifelong protection against heat, humidity, moisture, and everything in between.

The Colorimetry Process to Meet the Client's Needs

To meet the needs of the client's specific color finish, the Parklex team traveled to Valencia, Spain, to find the perfect wood veneer. Having selected a wood veneer that would meet the requirements, Parklex prepared samples, measured the color of them with a colorimeter and sent them to the client to evaluate.

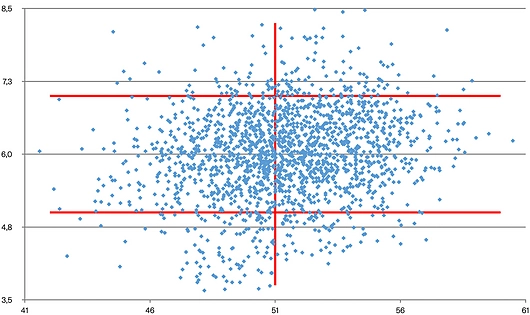

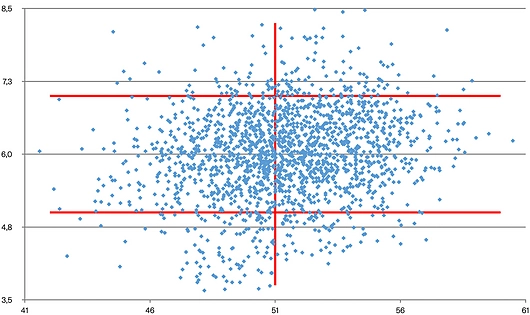

Colorimetry Scatter Map

This map shows the work that was required to achieve the perfect tone of wood. Thousands of samples were compared, with each dot representing the colour of each one.

The section marked ‘USA’ represents the samples that featured the desired tone of the client. These samples were the ones we eventually shipped to the United States.

Professional Service

PARKLEX PRODEMA is well aware of the challenges faced by architects and construction companies, having more than 50 years of industry experience. The need for their knowledge and professional service in seeing their products through to building completion was an important factor in the design of the bathrooms in the new tower.

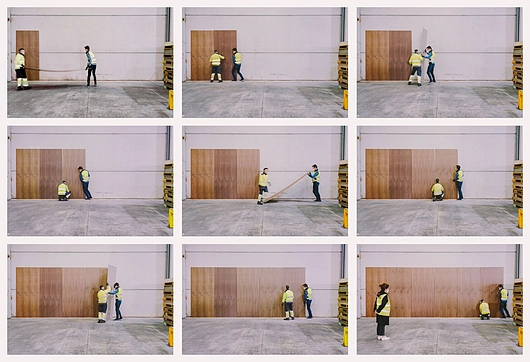

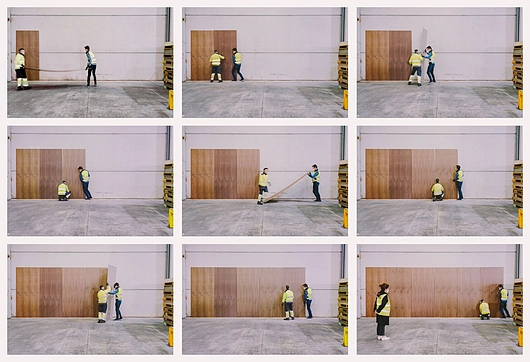

The panels had to be shipped uniquely to the USA. The panels were shipped in 52 boxes separated per floor for the tower. Each box containing a package for the woman's and men's bathroom. This guaranteed that each group of panels was installed in the proper location, with no room for error.