-

Use

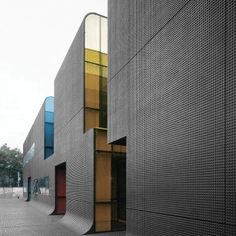

Facades -

Applications

Exterior -

Characteristics

Easy installation, durable, low maintenance, technical assistance available, acoustic performance, curved facades -

Sizes

50 X 150mm, 50 x 200mm, 50 x 300mm -

Certification

Fire Rating:, non-combustible under AS 1530.1-1994. -

Guarantee

Project specific warranties available

Sculptform’s Façade Blade system is specifically designed and engineered for large scale external facades. The key to the system is the mounting rail, which is fixed to the structure at the required spacing and has preset locations for the blade sequence. Prefinished blades are then easily connected to the mounting rail. The system has been designed for large spans and to maximize design flexibility while maintaining ease of installation.

There are three blade sizes available with the spacing customizable by the architect or designer. Typically the blades are spaced between 150 – 300mm apart but can be as close as 100mm. Blade spacing is an effective element for value management, as small changes can have a significant impact on overall system cost. Each blade has a matching end cap and back cover strip. Sculptform’s timber look wrap provides a realistic timber aesthetic to battens while taking advantage of the strength and fire resistance of aluminum.

Sculptform’s Façade Blade System uses a proprietary rail mounting brackets to mount the rail to the substrate, typically at 2.4m increments. Allowing for in/out and up/down substructure tolerance adjustments of up to +-25mm, the brackets use serrated components to lock into place at the desired position. These rail mounting brackets make it fast and simple to apply Sculptform’s Facade Blades to a variety of substructures including steel mullions, blockwork walls, and slab to slab applications.

Sculptform’s Price and Spec app allows architects and designers to quickly envisage, budget and specify their project. The app has a drag-and-drop feature to test cladding options while receiving real-time pricing, specification data, and 3D views. Sculptform also assists with making sure their products are expertly installed by offering an optional supply and install service.

About Sculptform

Sculptform manufacture modular wall, ceiling and facade systems that help designers realize their creative vision. Passionate collaborators in the design process, Sculptform pride themselves on being world leaders in having the products and know-how to turn a concept into a tangible architectural solution.

Used all over the world, Sculptform products are manufactured in their Australian factory to the highest level of quality for which they have become known.