Acoustical Surfaces CFAB™ cellulose acoustical panels are composed of 65–75% recycled fibers, providing a sustainable alternative for sound absorption. The panels are lightweight, cost-efficient, and simple to handle and install. They are typically applied to walls or ceilings using adhesives, with pins and washers as additional fastening options.

Product Characteristics

- Controls reflections and deadens sounds within a room

- Easy to handle and install – No special equipment required

- Resists mold growth

- Made from renewable and recycled fibers

- Low VOC Emissions – Passes CDPH V1.2 Test Standard and can contribute to LEED V4.1 EQ Credit: Low-Emitting Materials

Applications

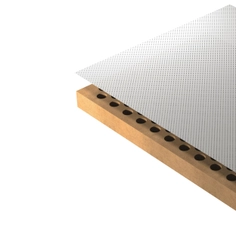

CFAB™ Typical applications include industrial and mechanical facilities, breweries and tap rooms, or as absorptive layers behind stretched fabric, slatted wood systems, or other finishes. They can also be installed beneath furniture or in spaces designed with an industrial or recycled aesthetic.

- Insulation components

- Office panels

- Acoustic panels/inserts

- Molded, flat panel, or lofted parts

| CFAB™ Panel Surface Detail | |

Sustainable Qualities

CFAB™ cellulose products are recyclable and don't produce scrap during manufacturing or installation. Through an innovative manufacturing process, the eco cell is produced as a cellulose-based product made primarily from post-consumer and post-industrial paper, with recycled newspaper as the main raw material.

Acoustical Performance

The open design and density of CFAB™ cellulose insulation panels increase sound absorption to control and deaden sound reverberation and echo. CFAB™ cellulose acoustical panels achieve high Noise Reduction Coefficient (NRC) ratings based on the density specified.

CFAB™ Cellulose Panels – Acoustical Testing Data

Absorption Coefficients @ Octave Band Frequencies (Hz)

| Thickness | 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | NRC |

| ½″ | 0.05 | 0.09 | 0.33 | 0.64 | 0.87 | 1.01 | 0.50 |

| 1″ | 0.09 | 0.26 | 0.84 | 1.05 | 1.05 | 1.05 | 0.80 |

| 1½″ | 0.14 | 0.40 | 0.93 | 1.09 | 1.03 | 1.03 | 0.85 |

| 2″ | 0.39 | 0.63 | 1.18 | 1.11 | 1.06 | 1.09 | 1.00 |

CFAB™ Cellulose Panels – Physical Property Data

| Property | Test Method | Value |

| Surface Burning Characteristics | ASTM E-84, UL 723 | Flame Spread: 15

Smoke Developed: <450 (Class A) |

| Critical Radiant Flux | ASTM E-970 | >0.12 w/cm² |

| Corrosiveness | ASTM C-739 | Acceptable |

| Fungal Growth | ASTM C-1338 | Acceptable |

| Thermal Resistance | ASTM C-518 | 3.6 – 3.7 R per Inch |

| Moisture Absorption | ASTM C-739 | Acceptable |

| Odor Emission | ASTM C-1304 | Acceptable |

Densities

- 1" 3 lb. pcf

- 1.5" 3 lb. pcf

- 1" 6 lb. pcf (minimum order may apply)

- 1" 8 lb. pcf (minimum order may apply)

- 2" 3 lb. pcf

Sizes

- Standard Size: 24" x 48"

- Additional Sizes: **12" x 12", 24" x 24", **48" x 48", 48" x 96"

- **Minimum quantities apply, please call for details.**

Product Safety

CFAB Cellulose panels contain flame retardants to ensure maximum safety for building insulation and carry a Class A fire rating. To protect against mold growth, CFAB cellulose panels contain an EPA-registered fungicide. CFAB does not contain any harmful airborne particles, and do not itch or irritate skin.

Explore Acoustical Surfaces' product catalog or visit their website for more information.