Grespania's Coverlam is the result of years of research and development. With the introduction of technology press lamination, today it's possible to produce 300x100cm large format technical stones, with a thickness as thin as 3.5 mm, that maintains the mechanical properties and the aesthetics of technical stones. This way the scope of porcelain uses and applications expands, offering great potential for innovation in the construction and interior design fields.

The limits on size and thickness formerly imposed by ceramics can now be surpassed.

Productions

Coverlam is a laminated large format technical stone 3 mm thick produced by mixing the natural raw materials, ground together with water, compacted using a technologically-advanced pressing system, and then fired in a novel hybrid kiln (gas and electricity), which amongst other things enables major reductions to be made in CO2emissions.

Use and Applications

- Heavy transit areas

- Interior & Exterior Walls & Floors

- Facades:

Coverlam can provide any project with innovative construction solutions due to its state-of-the-art features. Two examples illustrate this point: thanks o its large size, it is possible to install a facade in fewer steps, and the great versatility of its multiple formats ensures that it can adapt to any dimensional requirement.

Given its minimal thickness, Coverlam is one of the lightest facade covering materials in the market. That's why Coverlam is highly recommended for the implementation of ventilated facade projects.

Grespania Ventilated facades:

- Exposed clamp and concealed clamp: anchorage systems designed for ceramic of traditional format and thickness (8-12mm).

- Chemical bonding: concealed anchorage system designed for Coverlam thicknesses (3.5 to 5.6mm).

- Hodden anchor: concealed anchorage system for traditional thicknesses that allows easy replacement in case of maintenance.

The wide variety of Coverlam formats makes it the perfect solution to meet a project's facade modulation requirements. Given how easy it is to handle in construction work and to install on facades, Coverlam greatly reduces problems of replacement that often arise during the maintenance of a ventilated facade. Despite the reduced thickness, Coverlam is able to withstand the stresses to which covering materials for ventilated facades are typically subjected.

- Medical Facilities: Thanks to its large size, which reduces the number of joints, and its technical characteristics, Coverlam is especially suitable for paving and wall coverings in hospitals, clinics, and doctors' surgeries. It is resistant to chemical attack, easy to clean, and prevents the appearance of mold, bacteria, and fungi. It is now possible to enhance the bactericidal effect of Coverlam thanks to the H&C tiles photocatalytic coating. Available in 5.6mm thickness.

- Refurbishment: Coverlam can easily be placed on walls and floors, over the top of any material without the need for demolition. This eliminates the typical inconveniences associated with renovations, such as noise, dust, and debris, thus reducing working time. It's the minimal thickness and low weight facilitate storage and transportation and do not overload the existing structure.

- Interior Design: Coverlam's 100x300cm format makes it a suitable material for covering large surfaces, providing all the mechanical and aesthetic characteristics that distinguish technical stone tiles. Thank to its easy cutting and handling, Coverlam is the ideal material for covering fixtures or surfaces that require exacting finishes.

Features

- Coverlam is structurally reinforced by means of a glass fiber mesh 0.5 mm thick adhering to the back, endowing it with optimal mechanical strength.

- Available in a wide variety of shapes and sizes.

- Coverlam is considerably easier to cut and handle and notably reduces the logistical costs of packing and transport.

- Coverlam is resistant to bending, UV light, attack by chemicals, wear, fire, and frost.

- Coverlam is recyclable and the manufacturing process achieves the highest degree of respect for the environment.

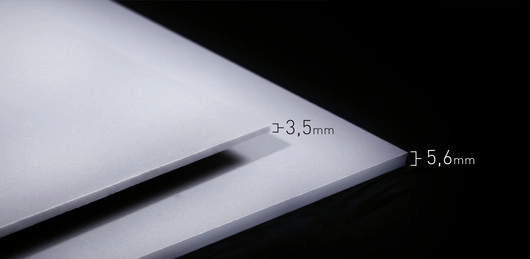

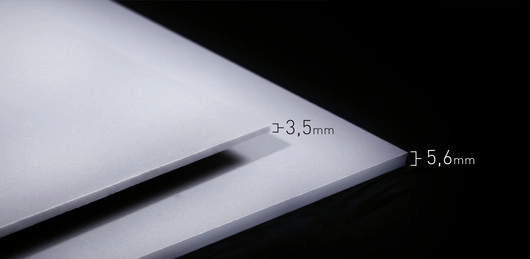

- Minimal Thickness:

Due to its reduced thickness – 3.5mm and 5.6mm – Coverlam only weighs 7.8 kg/m2 and 14 kg/m2, respectively. This makes cutting and handling far easier. As a result, Coverlam offers substantial financial savings in projects by enabling faster completion times. - Large Format:

Coverlam 3.5mm and 5.6mm is produced in 100x300cm rectified pieces and is solid in various formats, created by dividing up the initial piece with an automated cutting system. The 3.5 mm-thick Coverlam models comprise a 3 mm-thick porcelain base with a 0.5 mm-thick glass fiber mesh attached to the reverse side. As a result, the mechanical strength of the piece is substantially improved.

Sustainability

Coverlam's minimal thickness has enabled the development of a sustainable and extremely environmentally-friendly production process. To start with, the consumption of raw quarry materials is two-to-three times lower than any of the other types of technical stone tiles, in addition, Coverlam production requires less energy, thus allowing the use of a hybrid kiln (gas and electricity) and reducing CO2 emissions per year.