-

Use

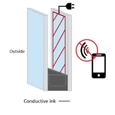

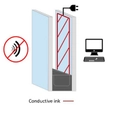

Electrically heated windows, glass radiators, alarms and security glass, anti-radiation glass, light effects -

Applications

Facades, curtain walls, wall covers, glass partitions, windows, doors, furniture, art and signage, lighting -

Characteristics

High performance, with long-lasting durability, high-resolution digital print (no screens), highly-customizable through digital design, resistant to scratching, acid, UV light and weather, heavy metal-free inks (no Lead), compliant with industry standards -

Format

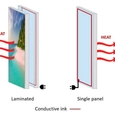

Single panels, laminated glass, insulated units, curved glass, jumbo glass -

Colors

Silver -

Sizes

Printable glass size: Minimum: 12” x 12” (30.48 cm x 30.48 cm) | Maximum: 118” x 314” (300 cm x 800 cm) | Printable glass thickness: Minimum: 3/16” (4.76 mm) | Maximum: 3/4” (19mm)

The product has been saved to the folder:

My Downloaded Products