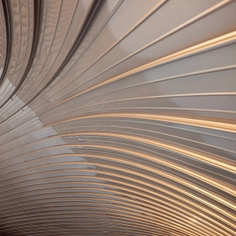

Euramax uses the coil-coating process to provide finishes for metal products that last a lifetime. Multiple coating layers are applied; after every coating layer, there is an oven step. Multiple aluminum alloys are available on which virtually every color can be applied.

Dual Tone Finishes

These coatings offer dual-tone color that changes depending on viewing angle and incidence of light. Custom projects can be used to develop dual-tone colors and gloss finishes. Install dual tone panels in the same direction to avoid color difference and order projects in one batch to avoid color difference.

Top Coating

All dual tone finishes are built up of at least 3 layers of PVDF topcoats offering UV protection, long warranty periods, and potential use across the globe. PVDF paints have a standard gloss of 30 gloss units. High gloss levels up to 90 g.u. or as low as 10 g.u. are possible by choosing a special FEVE top layer. In addition to gloss variation, the FEVE top layer offers anti-graffiti and self-cleaning properties. A Protec maximum corrosion resistance layer is also available for this range.

EuramaxLab Support Services

Euramax has a specification team that supports architects in specifying coated surfaces with in-depth experience in coating for cladding panel fabrication. The team; EuramaxLab helps to provide architects with an extensive choice in metal envelope design and work side by side with their customers to understand their business, needs, and challenges.

- Custom coating development

- Custom color development

- Precision color matching

- Metal sampling

- Mockup service

- Network of panel manufacturers

Finishes

| | | |

| White Green | White Gold | White Silver |

| | | |

| Arctic Grey | Seafoam Silver | Emerald Silver |

| | | |

| Gold Silver | Sapphire Blue | Ocean Blue |

| | | |

| Green Red | Amethyst Purple | Penny Copper |

| | | |

| Black Titanium | | |