-

Use

Sun-shading, facades -

Applications

Transport, public -

Characteristics

Tailor-made precast facades, standardized panels, durability, low-porosity, resilience, ductility, fiber-reinforced UHPC, low maintenance -

Format

Panels -

Sizes

Panel width: 1.37m | Panel height: 1.18m

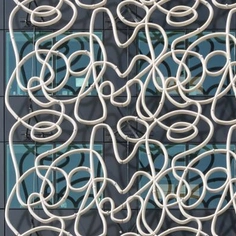

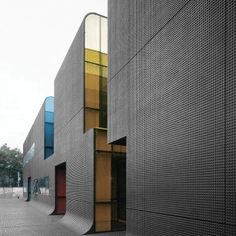

Ductal® Brise Soleil Facades provides an innovative solution for sun-shading in Kenitra Train Station. The station is one of the strategic points of Morocco’s high-speed rail route between Tangiers and Kenitra, and a symbol of economic development in the country. The rail line will connect urban areas and business zones adjacent to two economic centers, composed of the two Moroccan maritime hubs: the Atlantic Port of Casablanca and the Mediterranean Tangiers Med.

A facade worthy of its role was required the Moroccan architect Omar Kobbité, a partner in the Italian firm Silvio Dascia, rose to the challenge with a Ductal® facade. The Ductal® fiber-reinforced UHPC material enables original shapes to be designed (in this case, triangles) standing out from traditional materials and designs, reinforcing the feeling of innovation and dynamism for the high-profile project.

The building’s facade measures 6,225 m² and is made up of around 4,175 3D Ductal® panels, triangular in shape and white on both sides. Measuring 1.37 m wide by 1.18 m high, and between 1.5 cm (in height) and 2 cm thick (for greater resistance at ground level), these monolithic panels are composed of a flat plane, the exterior surface, and a vertical return, which allows inserts and attachments to be installed in order to attach the concrete panels to the building’s metallic structure. All wood and glass parts are assembled on-site once the facade panels were installed.

Although the elements appear identical, with a sober design, the triangular panels were complex to calculate and install, and slight adjustments were required in order to achieve the expected outcome. Engineers from the Ductal® pre-caster, BEARCH, who supplied the panels for this project, had to utilize both their knowledge and the special characteristics of the Ductal® fiber reinforced concrete material in order to find a solution that was both technically and economically viable, enabling the panels to be aligned while absorbing any dimensional deviations from the metallic structures.

Data

| Location | Kenitra, Morocco |

| Delivered in | 2018 |

| Architect | Omar Kobbité partner in the Italian firm Silvio Dascia |

| Precaster | BEARCH |

| Facade | 6225m²; 4175 3D panels in white Ductal® |

Why Ductal®

In this case, the facade not only envelops the structure but also acts as a sun-breaker so as to limit the light entering the station. The durability of Ductal® also ensures the facade’s longevity and stability when faced with external stresses (impacts, differences in temperature, dirt, and pollution, sun, etc.). The perfect appearance and sustainability of the material, already tested on other projects in Morocco, such as Casa Port, were the two decisive arguments for both the client and the architect when choosing the material