-

Use

Interiors and sheltered exteriors -

Applications

Timber cladding, curved walls, curved ceilings, bulkheads, seamless transitions, 3D effects, curved trims -

Characteristics

Customizable, concealed fixings, fast installation, adapts to fit budget, large-scale production

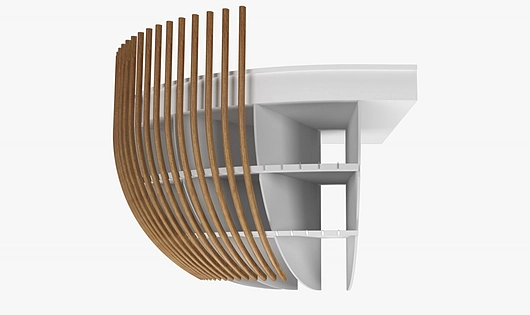

Creating curved timber forms is a complex process, and often difficult to effectively achieve on a commercial scale. Sculptform's Curved Timber Battens allow designers to create buildable, affordable solutions for curved concepts.

Due to the properties of wood and its susceptibility to movement, the right manufacturing option needs to be considered when creating curved timber. Sculptform has two options for integrating curved timber into a design – Steam bending and Kerfing, which both utilise their Click-on Batten System for simple, fast installation.

Sculptform curved timber battens utilise the modular nature of their batten system, allowing designers to achieve concepts that have previously been too complex or expensive to deliver effectively. Sculptform's internal pre-construction team are experts at leveraging their products to deliver on a concept.

Curving Methods

| Steam Bending | Kerfing |

| Sculptform's process takes principles from the traditional art of steam bending, applied on a much larger scale. Timber battens are heated to high temperatures under strict moisture conditions until malleable, then curved in a form and held in place until cooled and dried. | The process of kerfing allows the battens to curve by cutting a series of small notches in the back of each batten, allowing for extra flexibility. The pre-kerfed battens are delivered to site, where they can quickly be installed to the existing form with a curved mounting track. |

Features & Benefits

- Large scale curves

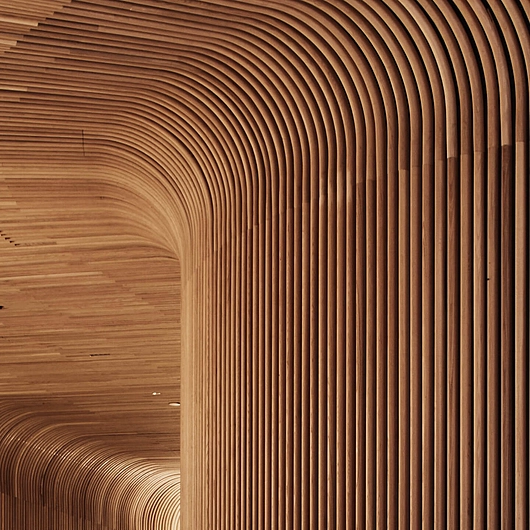

The methods used to create curved timber can be employed to create large scale curves in natural timber. Seamless transitions between planes such as a wall and ceiling provide a unique handcrafted aesthetic on a commercial scale. - Systemising the sculptural

Large scale timber manufacture is made possible by combining the bending process with the Sculptform Timber Click-on Battens System. The benefits of the established system carry across, ensuring customisation and fast, accurate installation. - Range of options

For unrestricted design with curved timber, two different methods of bending can be utilised – Steam bending and Kerfing. Each of these methods has a range of strengths, offering a solution that meets the unique requirements of each project. - A wide range of applications

The system is extremely versatile and can be used in a variety of interior applications such as transitions between walls and ceilings, or impressive bulkheads. The Kerfing process can also be used for sheltered exteriors like in Sculptform's Arkadia Apartments project.

Click here to learn more about this product.